Technical Parameters

Model No.

AD12025ET6

Cutting Area

12000x2500mm

Tube Diameter

φ10-220mm □10-220mm(Optional 350 chuck)

Tube Length

3000mm / 6000mm optional

Max Tube Weight

300kg

X/Y Positioning Accuracy

±0.05mm/m

X/Y Repositioning Accuracy

±0.04mm/m

Maximum Movement Speed

100m/min

Laser Power

6000W-20000W

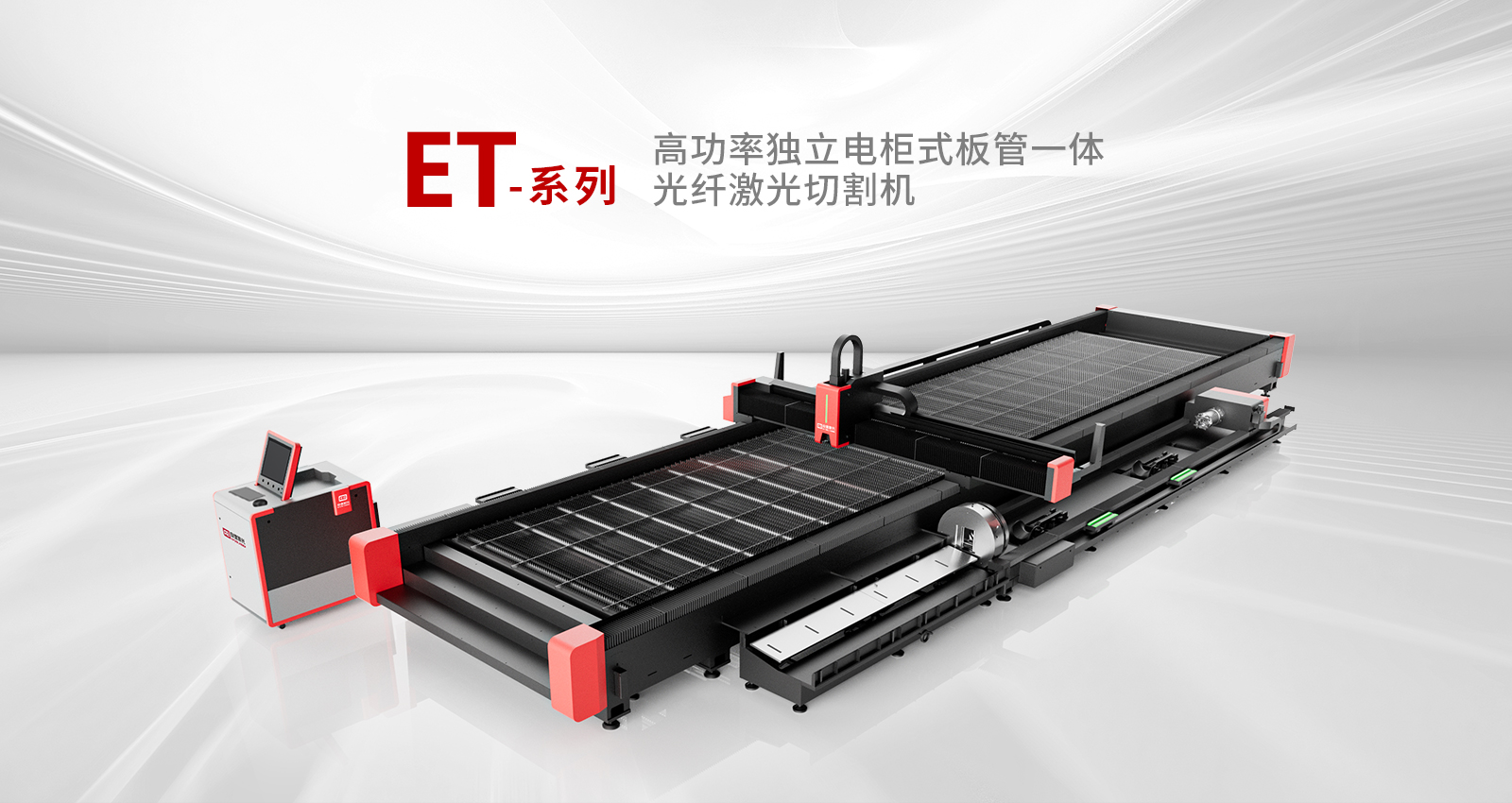

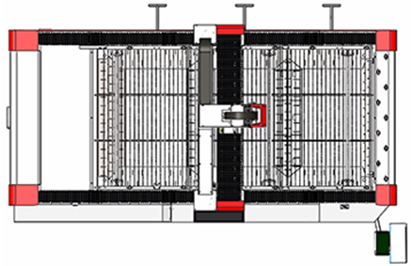

Open Bed Design for Cutting Platform

• Movable electric cabinet and operational panel, friendly to operators.

• Convenient for loading and unloading material, easy maintenance.

Independent Control Cabinet

• The control cabinet is equipped with air condi-

tioner for automatic temperature adjustment,

which can prevent excessive heat damage to com-

ponents.

• Operator does not have to be close to the ma-chine, which effectively prevents cutting sparks

dust and accidents.

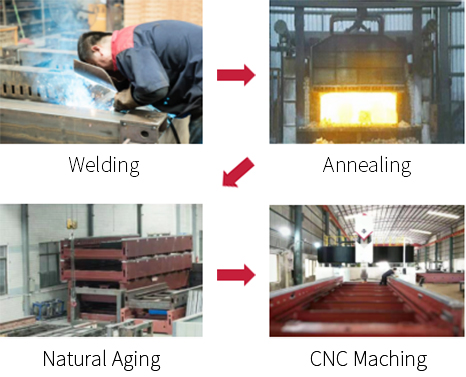

Hive-style Steel Plate Welding Structure

One-piece Extruded Aluminum Beam

•Based on the metal characteristics of aeronautical engineering aluminum alloys, it has lightweight and high rigidity,which ensures high-speed motion during laser processing.

•Perfect dynamic performance. under the condition of satisfying accuracy,high-speed cutting ofvarious graphics canbe achieved.

•Long service life, it can keep the shape unchanged to themaximum extent, so as to ensure the cutting accuracy andproduct quality.

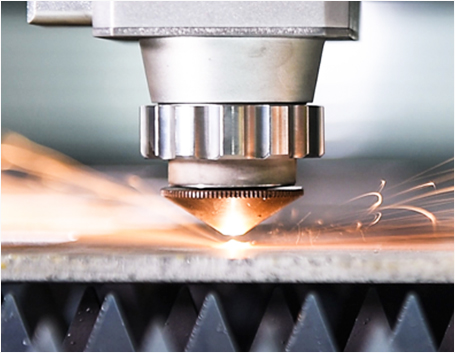

High Quality Configuration

• Power operating range:10%~105%

• Light beam mass: BPP<2.5

• Service life of pumping source: 100,000h

• Maintenance free

• Collimator lens and focus lens are equipped in drawers installation way, whichis convenient for maintenance and replacement.

• Adopting water-cooling heat sink inside to reduce the temperature of the cut-ting head to improve its service life.

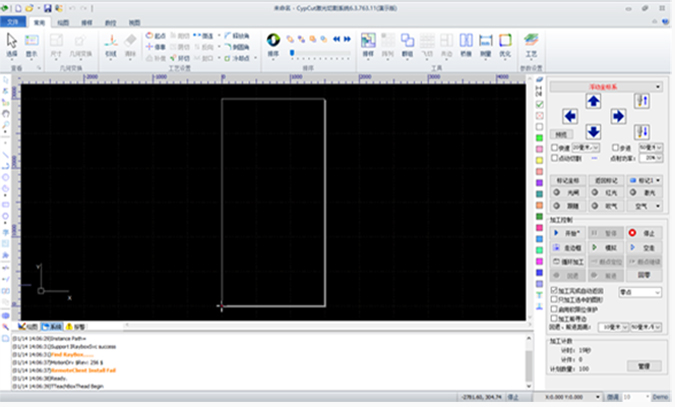

Professional Control Software

• Support for DXF, PLT, LXD and other graphic data formats.

• Find edge: up to 500mm/s high speed with precision find sheet edge, alsoprovide optional find edge patterns to meet your production needs.

• Supports laser power control, in-flight cutting and jump, continuous cut-ting at a breakpoint, automatic edge search, keyhole processing, cuttinghead control, and etc.

• Technique: multiple piercing solutions for metal sheet of different thick-ness; piercing slags removal; vibration suppression; close-loop gas con-trol; separate layer technique for large, medium and small contour cut-ting, all to expand your machine production capability.

Imported Component Parts

• Automatic parallel compensation technology.

• lmprove processing range.

• Less mechanical components and motors cost.

• Increased running speed.

• Good dynamic response.

• High precision and speed, large inertia ratio.

• Stable performance and durability.

• Excellent dynamic response.

• Closed loop control method.

• Quiet,non-polluting, reliable and long-lasting.

• Achieve high precision and speed in cutting process.

• Excellent quality and stability, in accordance with internationalstandards.

Professional Water Chiller

• High precision temperature control function. Temperature control accuracy can reach ±1°C High temp. for QBH connection/ optics and low temp. for laser devices.

• Multiple alarm protection: The laser will stop working once it receives the alarm signal from the water chiller for protection purposes.

• Equipped with water pressure gauges, drain outlet with valve, and universal wheels. Water pres.sure gauges help monitor the discharge pressure of the water pump while universal wheels facilitate the moving of the chiller.

• Dualinlet and dual outlet connector& level gauge equipped. The Chiller inlet connects to the laser outlet connector. The Chiller outlet connects to the laser inlet connector.

• Cooling fan of famous brand installed. With high quality and low failure rate.

• Customized dust gauze is available and easy to take apart.

Other Important Accessories

S&A Chiller

Taiwan Precision Guide Rail

Taiwan Pinion and Rack

Imported Reducer

Imported Servo Motor

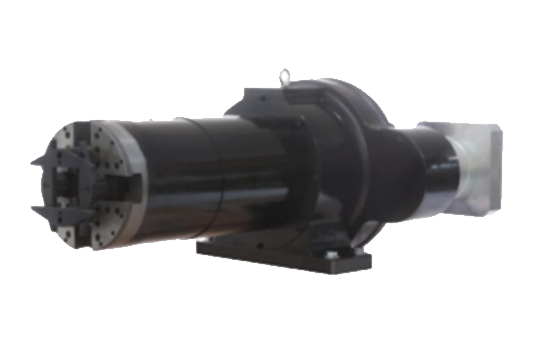

Full Stroke Pneumatic Chuck

Professional Clamp Design

Fractional Automatic Support Installation

• lt adopts a pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-220mm

• Automatic pneumatic chuck, adjustable and stable.

• Non-destructive pipe clamping.

• Fast automatic centering and clamping pipe.

• Gear transmission mode, higher transmission efficiency.

• lt employs intelligent tube support design,which can solve the deformation problemsin the process of long tube cutting.

Ande Services

Quality Control

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

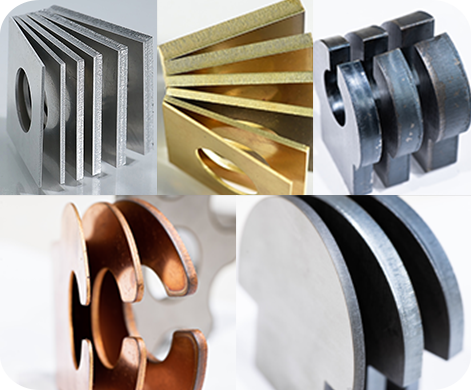

Cutting Samples

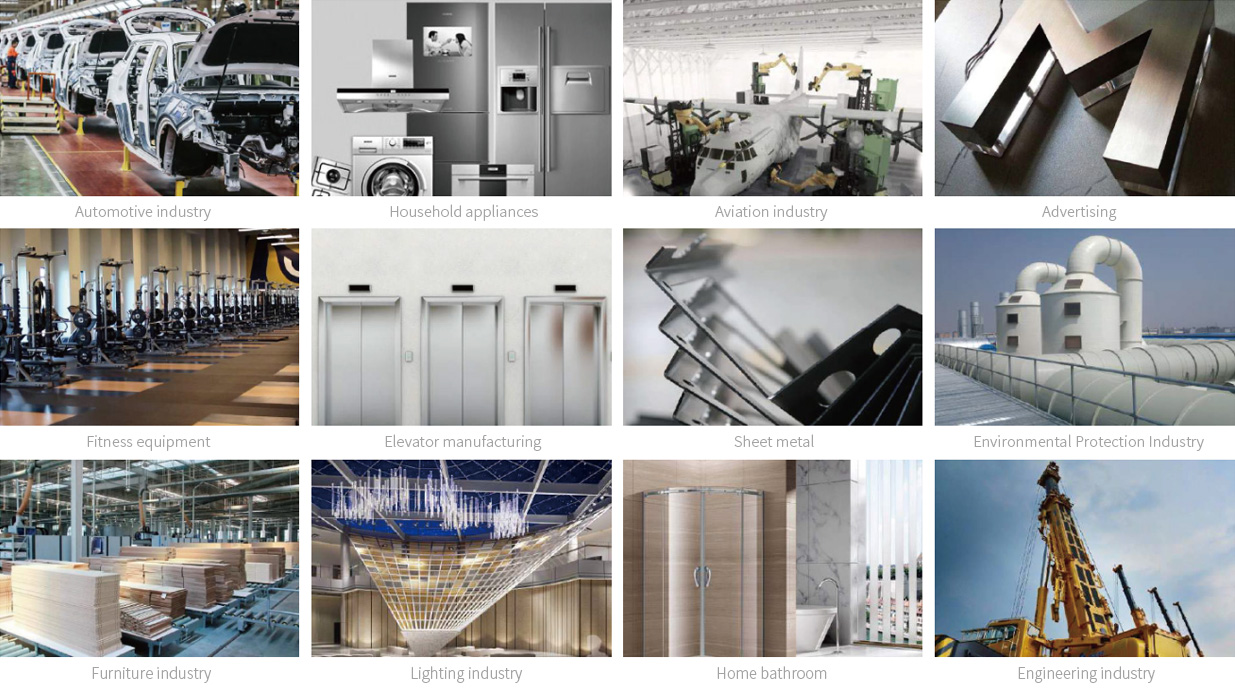

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.