Technical Parameters

Model No.

ADLFW-1000

ADLFW-1500

ADLFW-2000

Laser Power

1000W

1500W

2000W

Laser Wavelength

1080±5nm

Working Mold

Continuation / Modulate

Power Adjustment Range

10-100%

Positioning

Red Light

Length Of Fiber-optical

10m

Welding Speed Range

0-120mm/s

Material Thickness

<3.5mm(Depends on the material)

Wire Feeder

Standard,wire feeding speed 38-600mm/min

Wire Diameter

0.8 / 1.0 / 1.2 / 1.6 / 2.0 mm

Cooling Method

Water Cooling

Comparative Analysis of Several Different Welding Methods

Type

Traditional Welding Machine

Solid YAG Welding Machine

Ande laser new laser welding machine

Welding Qualitly

Heat Input

Workpiece Deformation

Welds Forming

Post-Processing

High

Large

Fish scale

Polish

Low

Small

Fish scale

Polish

Low

Small

Smooth

None

Operation

Welding Speed

Operation Difficulty

Slow

High

Medium

Slow

Fast

Small

Environmental Protection and Safety

Personal Harm

Environmental Pollution

Large

Heavy

Small

Light

Small

Light

Operation Cost

Consumables

Energy Consumed

Welder Requirement

Occupied Area

Welding rod

Low

High

Small

Laser crystal, xenon lamp

High

Medium

Large

None

Low

Low

Small

Ande Laser Handheld Laser Welding Machine 6 Advantages·

Make Welding Easier.

Small thermal deformation

0 welding experience requires

1 day to get started

3 kinds of security guarantee

Efficiency increased by 2-10 times

Multiple spot type to

fulfill different request

360° moving at will

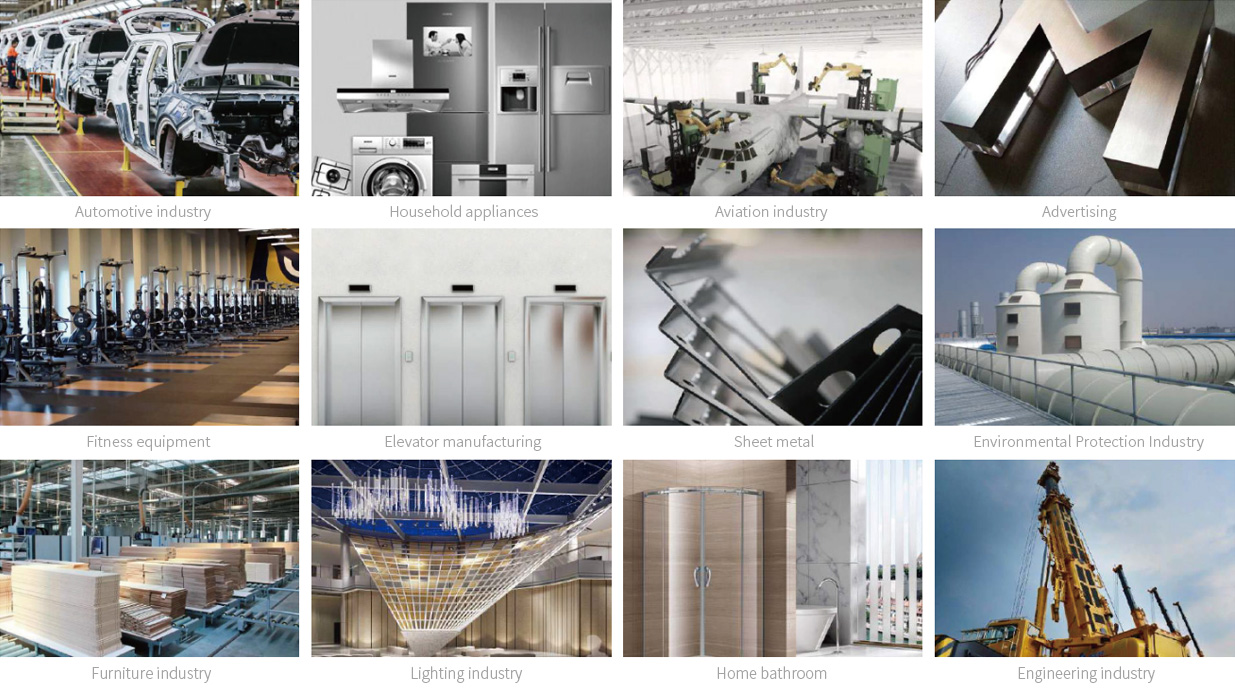

Wide Application Range In Different Material And Industry

• Widely used in combined welding like use with robot welding and other automatic welding methods.

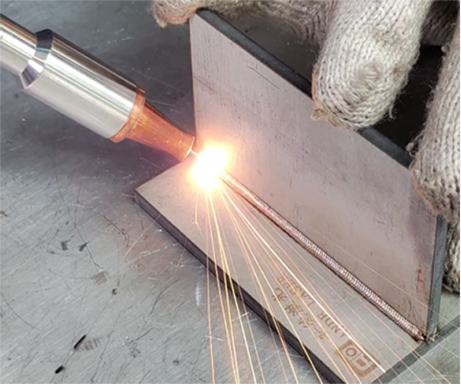

Smooth Weld Seam, Save Polishing Cost And Time

Beautiful welding seam and smooth welding effectsmall or even no need for further polishing.

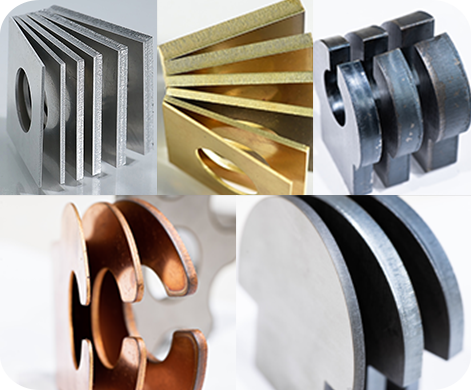

Multiple Welding Request Can Be Fulfilled

The welding head is equipped with a variety of copper nozzle, to meet the Butt Joint welding, Tee joint welding Corner joint welding, Lap joint welding, and other welding requirements.

Good Penetration

• In the welding of thin materials, fiber optic weldingimproves the yield rate by 159% compared to argonarc welding

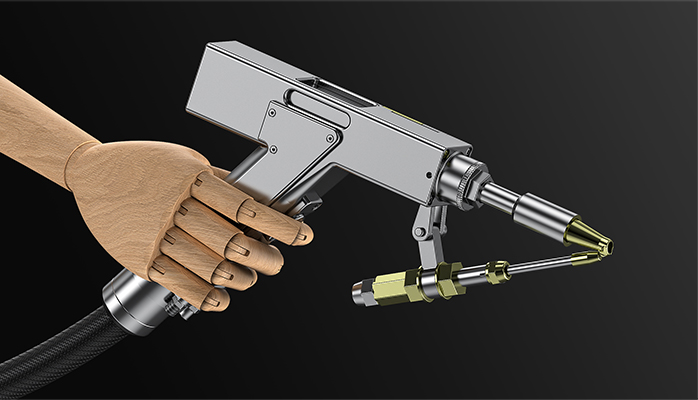

Flexible And Arbitrary Welding

Small and light welding gun, less than 0.8kg and meet the ergonomics design. Flexibly used in different welding position.

The professional ability to freely moveand weld large-sized workpieces

Standard 10-meter fiber cable, available for outdoor and large workpiece weldingEquipped with a universal wheel, free to move everywhere.

Ande Services

Quality Control

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

Welding Samples

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.