技術參數

Machine Model

AD3015FC

AD4020FC

AD6020FC

切割區域

3000x1500mm

4000x2000mm

6000x2000mm

X/Y 軸定位精度

±0.03mm/m

Max. Movement Speed

120m/min

Max. Acceleration

1.0G

激光功率

1000W-6000W

Max Loading Weight

650kg

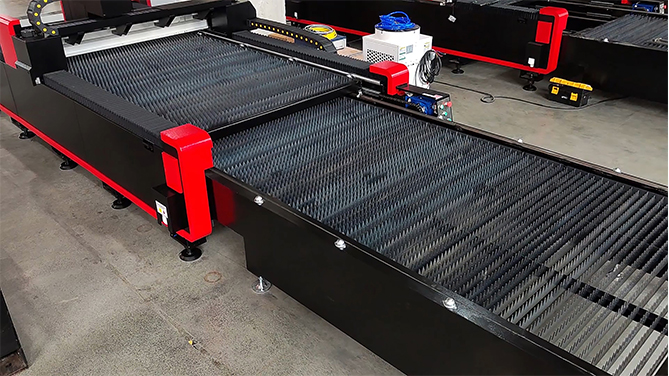

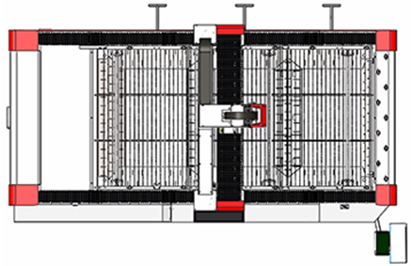

開放式床身設計的切割平台

• 可移動的電氣櫃和操作面板,方便操作人員使用。

• 方便裝卸物料,易於維護。

Exchange platform

• It can be cut at the worktable and loaded and unloaded at the same time to improve production efficiency; the platform ex-change time is less than 15s, and the large-format rapid ex-change saves time.

獨立控制櫃

• All electrical components and laser sources are

built-in to the independent control cabinet with an adust-proof design to prolong the lifespan.

• Operator does not have to be close to the machine, effectively preventing cutting sparks dust, and accidents.

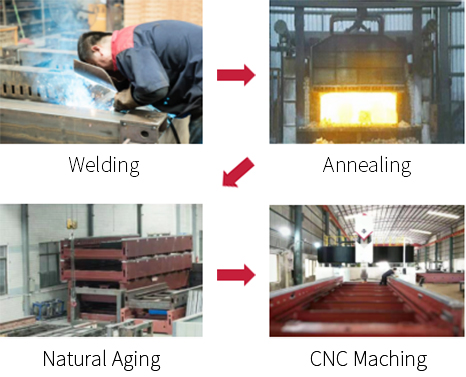

蜂巢式鋼板焊接結構

• The hive-type structure welding with steel plate, is a special geometry for aerospace, and its rigidity is the best to meet the requirements of high-speed motion, which can prevent deformation within 20 years and maintain the machine performance of high accuracy.

• The store-stain relation, fatigue life, and thermal field of the frame structures are analyzed using the finite element method. By selecting the most appropriate solutions in terms of materials and structure, the stability and precision of the machines are ensured.

• Manufacturing Process: welding main frame -completely de-stress annealing at 580’C -natural aping for more than half a year-vibration aping-roughing secondary vibration aging – semi-finishing – finishing – brushing protection paint.

一體成型擠壓鋁合金梁

•Based on the metal characteristics of aeronautical engineering aluminum alloys, it has lightweight and high rigidity, which ensures high-speed motion during laser processing.

•Perfect dynamic performance. under the condition of satisfying accuracy, high-speed cutting of various graphics can be achieved.

•Long service life, it can keep the shape unchanged to a maximum extent, to ensure cutting accuracy and product quality.

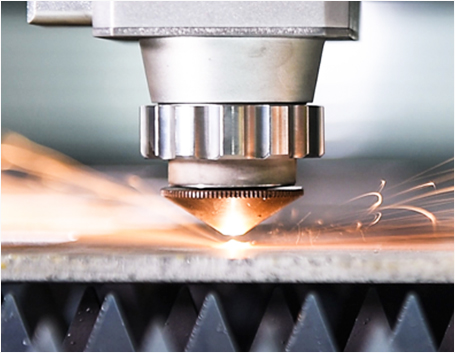

高品質配置

• 功率工作範圍:10%~105%

• 光束品質:BPP<2.5

• 泵浦源使用壽命:100,000h

• 免維護

• 準直鏡和聚焦鏡採用抽屜式安裝方式,方便維護更換。

• 內部採用水冷散熱器,降低切割頭溫度,提高其使用壽命。

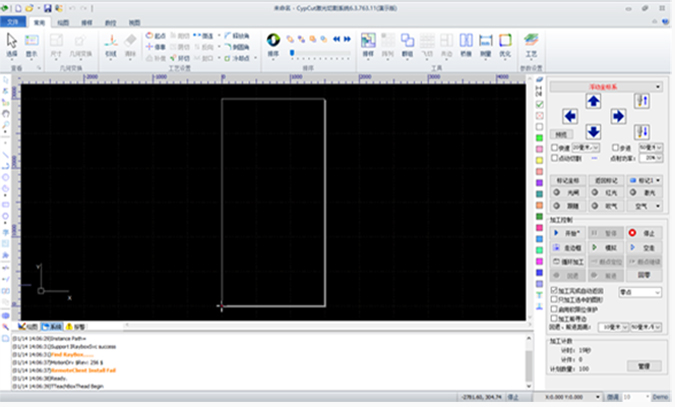

專業控制軟件

• Support for DXF, PLT, LXD, and other graphic data formats.

• Find edge: up to 500mm/s high speed with precision find sheet edge, also provide optional find edge patterns to meet your production needs.

• Supports laser power control, in-flight cutting, and jump, continuous cutting at a breakpoint, automatic edge search, keyhole processing, cutting head control, etc.

• Technique: multiple piercing solutions for metal sheets of different thicknesses; piercing slag removal; vibration suppression; close-loop gas control; separate layer technique for large, medium, and small contour cutting, all to expand your machine production capability.

進口零部件

• Automatic parallel compensation technology.

• lmprove processing range.

• Less mechanical components and motors cost.

• Increased running speed.

• Good dynamic response.

• High precision and speed, large inertia ratio.

• Stable performance and durability.

• Excellent dynamic response.

• Closed loop control method.

• Quiet,non-polluting, reliable and long-lasting.

• Achieve high precision and speed in cutting process.

• Excellent quality and stability, in accordance with internationalstandards.

Professional Water Chiller

• High precision temperature control function. Temperature control accuracy can reach ±1°C High temp. for QBH connection/ optics and low temp. for laser devices.

• Multiple alarm protection: The laser will stop working once it receives the alarm signal from the water chiller for protection purposes.

• Equipped with water pressure gauges, drain outlet with valve, and universal wheels. Water pres.sure gauges help monitor the discharge pressure of the water pump while universal wheels facilitate the moving of the chiller.

• Dualinlet and dual outlet connector& level gauge equipped. The Chiller inlet connects to the laser outlet connector. The Chiller outlet connects to the laser inlet connector.

• Cooling fan of famous brand installed. With high quality and low failure rate.

• Customized dust gauze is available and easy to take apart.

Ande Services

品質控制

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

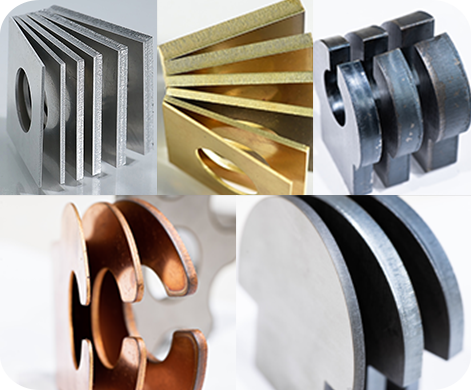

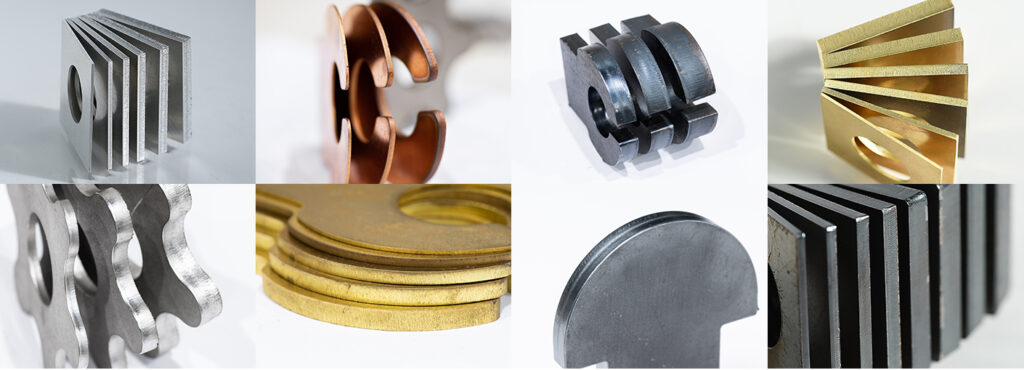

Cutting Samples

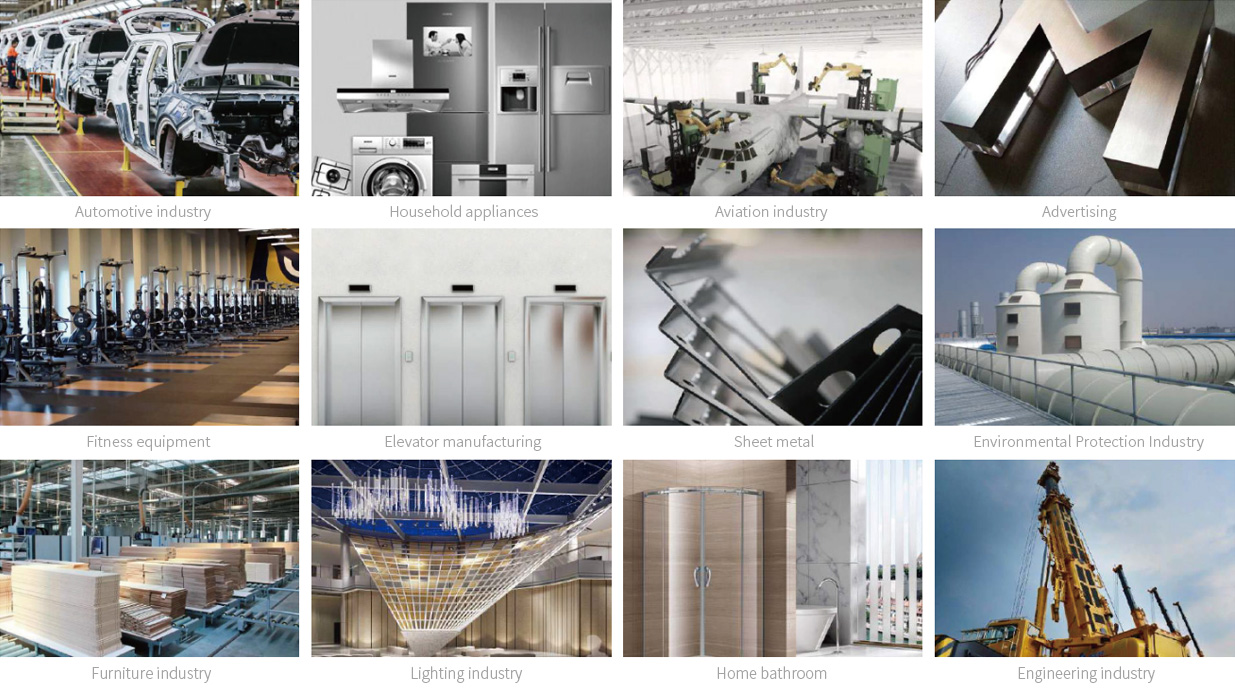

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.