trang chủ » Vật tư tiêu hao laser » Vòng đệm » Vòng đệm

trang chủ » Vật tư tiêu hao laser » Vòng đệm » Vòng đệm

detailed information

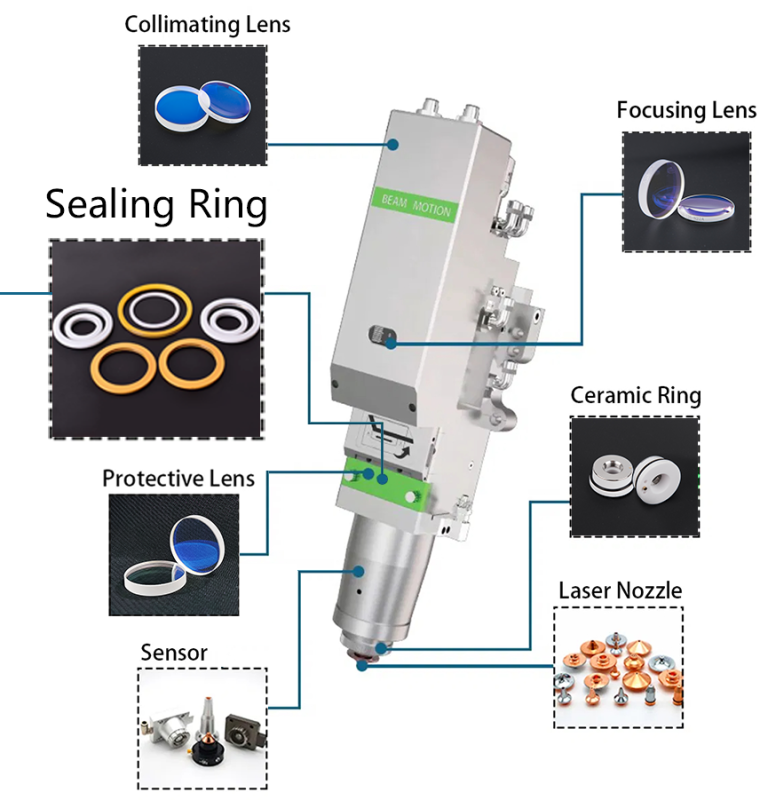

What is a sealing ring?

The sealing ring is wrapped around the edge of the protective lens and is located between the lens and the lens holder.

It prevents dust and slag generated by cutting from invading the lens surface, protects the inside of the lens holder and isolates external moisture and oil.

Dust and pollution prevention

It blocks metal dust, smoke and debris generated during the cutting process, avoids contamination of lenses and optical components, and significantly extends the life of the equipment

Protects precision optical systems

Isolates corrosive media such as water vapor and oil, avoids damage to lens coating or optical path deviation, and maintains laser focusing accuracy.

Shock absorption and buffering

Some spring energy storage sealing rings (such as PTFE+stainless steel spring structure) can absorb equipment vibration and reduce the risk of optical component deviation caused by vibration

Specification(mm):

Packaging:

Ande Laser Intelligent Equipment (Guangdong) Co., Ltd. is a professional manufacturer of laser machinery. Located in Jiangmen High-Tech Zone, Ande Laser holds ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System certifications and has earned recognition as a national high-tech enterprise. With a team boasting 20 years of industry experience, EU CE certification, and multiple patents, Ande Laser’s products are performing exceptionally well in the “Belt and Road” markets.

Our product range includes laser cutting machines for both plates and tubes, laser welding machines, laser marking machines, and laser cleaning machines. Ande Laser remains committed to the principles of digitization,standardization, and intelligence, with the goal of providing high-quality laser solutions to global enterprises and empowering industries through laser.

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

Product Consulting

Related Products