Parâmetros técnicos

Nº do modelo

AD3015F

AD4020F

AD6020F

Área de corte

3000x1500mm

4000x2000mm

6000x2000mm

Precisão de posicionamento X/Y

±0.04mm/m

Velocidade máxima de movimento

120m/min

Maximum Acceleration

1.0G

Potência do laser

1000W - 6000W

Max Loading Weight

650kg

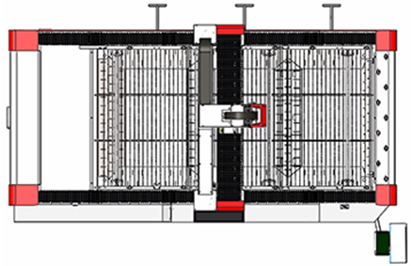

Exchange platform

• It can be cut at the worktable and loaded and unloaded at the same time to improve production efficiency; the platform ex-change time is less than 15s, and the large-format rapid ex-change saves time.

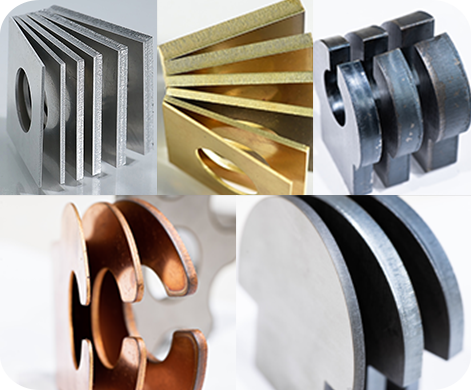

Suitable For Cutting A Variety Of Materials

• Suitable for cutting a variety of materials. No need for secondary processing, improves efficiency.

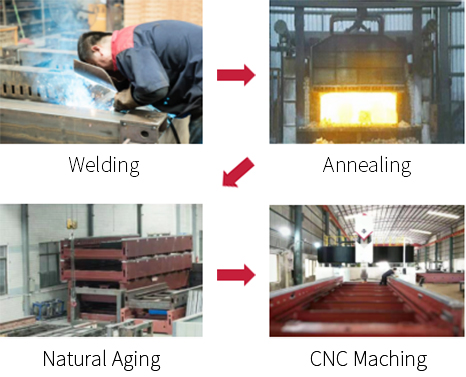

Estrutura de solda de chapas de aço tipo "colmeia"

One-piece Extruded Aluminum Beam

•Com base nas características metálicas das ligas de alumínio da engenharia aeronáutica, é leve e tem uma elevada rigidez, o que garante um movimento a alta velocidade durante o processamento a laser.

•Desempenho dinâmico perfeito. Sob a condição de precisão satisfatória, é possível obter cortes de alta velocidade de vários gráficos.

•Longa vida útil, consegue manter o formato inalterado ao máximo, de modo a garantir a precisão do corte e a qualidade do produto.

Configuração de alta qualidade

• Gama de potência de funcionamento: 10%~105%

• Qualidade do feixe: BPP<2,5

• Vida útil da fonte da bomba: 100.000 h

• Isento de manutenção

• As lentes do colimador e as lentes de focagem estão instaladas em gavetas, o que facilita a manutenção e a substituição.

• Dissipador de calor com arrefecimento a água no interior para reduzir a temperatura da cabeça de corte e aumentar a sua vida útil.

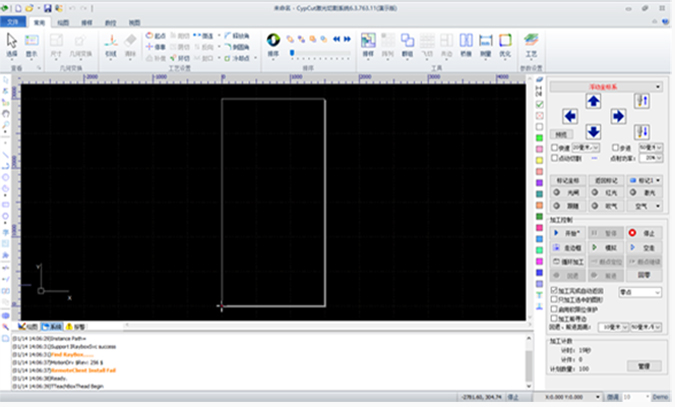

Software de controle profissional

• Suporte para DXF, PLT, LXD e outros formatos de dados gráficos.

• Localização das margens: alta velocidade até 500 mm/s com localização precisa das margens da folha, também fornece padrões de localização opcionais das margens para satisfazer as suas necessidades de produção.

• Suporta o controlo da potência do laser, o corte e o salto em voo, o corte contínuo num ponto de interrupção, a busca automática de arestas, o processamento do buraco da fechadura, o controlo da cabeça de corte e etc.

• Técnica: múltiplas soluções de perfuração para chapas metálicas de diferentes espessuras; remoção de escórias de perfuração; supressão de vibrações; controlo de gás em circuito fechado; técnica de camada separada para cortes de contornos grandes, médios e pequenos, tudo para expandir a capacidade de produção da sua máquina.

Peças importadas

• Automatic parallel compensation technology.

• lmprove processing range.

• Less mechanical components and motors cost.

• Increased running speed.

• Good dynamic response.

• High precision and speed, large inertia ratio.

• Stable performance and durability.

• Excellent dynamic response.

• Closed loop control method.

• Quiet,non-polluting, reliable and long-lasting.

• Achieve high precision and speed in cutting process.

• Excellent quality and stability, in accordance with internationalstandards.

Professional Water Chiller

• High precision temperature control function. Temperature control accuracy can reach ±1°C High temp. for QBH connection/ optics and low temp. for laser devices.

• Multiple alarm protection: The laser will stop working once it receives the alarm signal from the water chiller for protection purposes.

• Equipped with water pressure gauges, drain outlet with valve, and universal wheels. Water pres.sure gauges help monitor the discharge pressure of the water pump while universal wheels facilitate the moving of the chiller.

• Dualinlet and dual outlet connector& level gauge equipped. The Chiller inlet connects to the laser outlet connector. The Chiller outlet connects to the laser inlet connector.

• Cooling fan of famous brand installed. With high quality and low failure rate.

• Customized dust gauze is available and easy to take apart.

Ande Services

Controle de qualidade

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

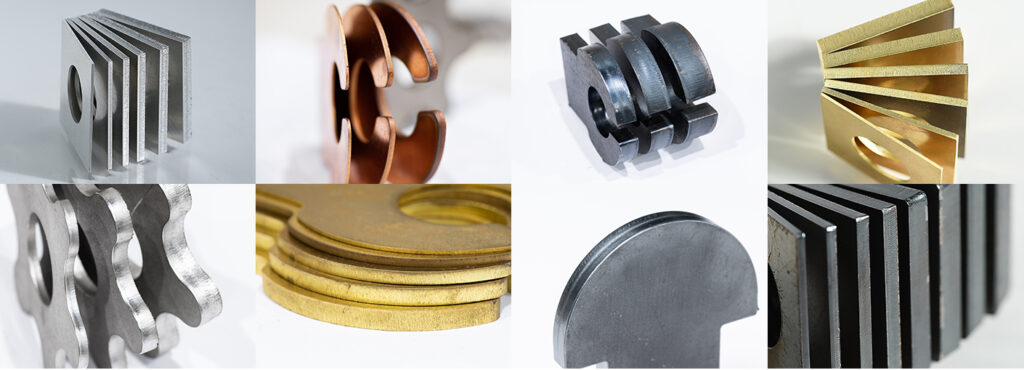

Cutting Samples

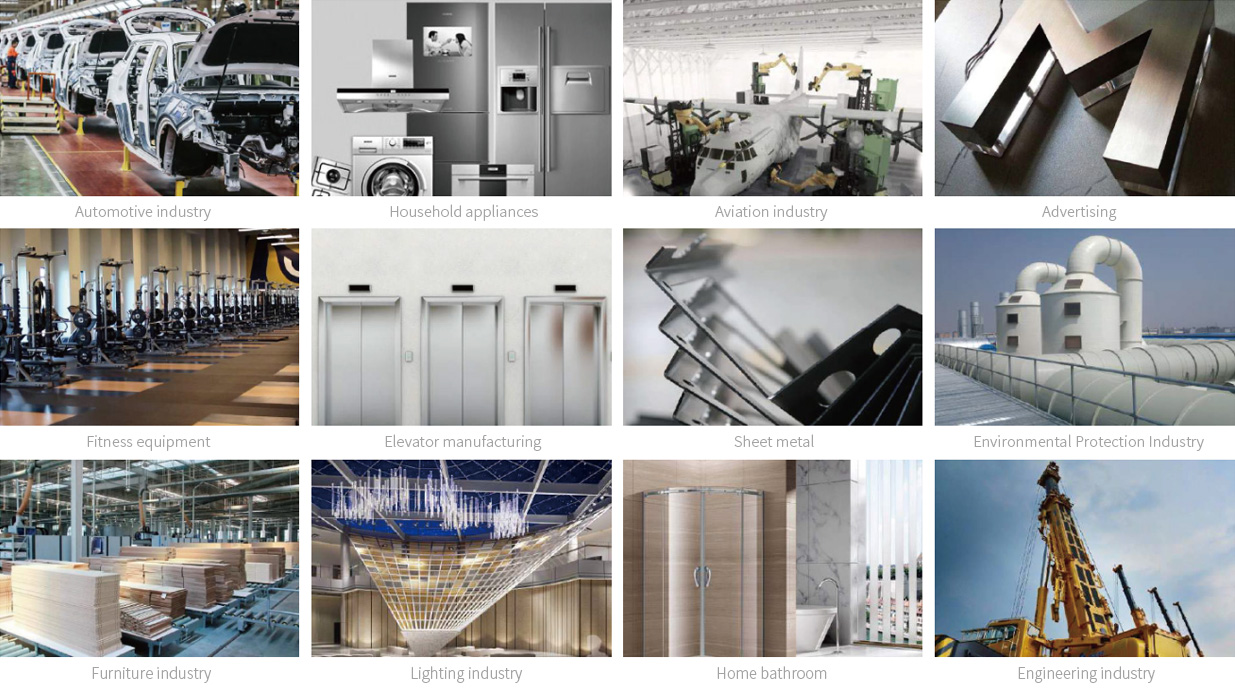

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.