기술 매개변수

모델 번호

AD3015ET

AD4020ET

AD6020ET

AD6025ET

AD12025ET6

절단 영역

3000x1500mm

4000x2000mm

6000x2000mm

6000x2500mm

12000x2500mm

관경

φ10-220mm □10-220mm (옵션 350척)

관 길이

3000mm / 6000mm 선택 사양

최대 관중

300kg

X/Y 축 정위치 정확도

±0.05mm/m

X/Y 재위치 정확도

±0.04mm/m

최대 이동 속도

100m/min

레이저 출력

6000W-20000W

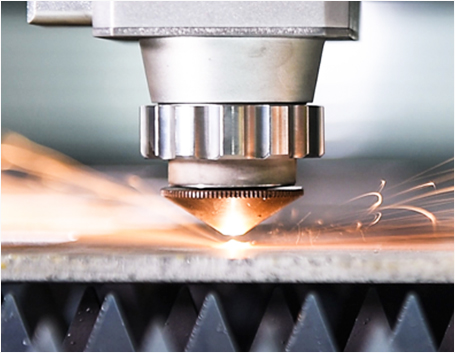

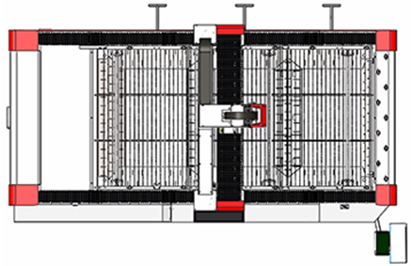

개방형 베드 디자인 절단 플랫폼

• 이동식 전기 캐비닛 및 운전대, 운전자에게 친절합니다.

• 물질 로딩 및 언로딩이 편리하고, 유지보수가 용이합니다.

독립 전기 제어 캐비닛

•제어 캐비닛은 온도를 자동 조절하는 에어컨을 장착하고 있으며, 이는 과열로 인한 부품 손상을 방지할 수 있습니다.

•작업자가 기계에 가까이 갈 필요가 없으므로 절단 불꽃, 먼지 및 사고를 효과적으로 방지할 수 있습니다.

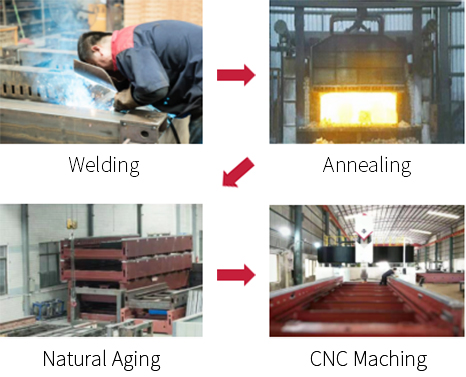

벌집식 강판 용접 구조

One-piece Extruded Aluminum Beam

•항공공학용 알루미늄 합금의 금속 특성을 바탕으로 가볍고 강성이 높아 레이저 가공 시 고속 동작을 보장합니다.

•완벽한 동적 성능. 정확도가 만족되는 조건 하에서 다양한 그래픽의 고속 절단이 달성될 수 있습니다.

•Long service life, it can keep the shape unchanged to themaximum extent, so as to ensure the cutting accuracy andproduct quality.

고품질 구성

• 전력 작동 범위: 10%~105%

• 광선 질량: BPP<2.5

• 펌핑 소스의 수명: 100,000시간

• 유지보수 불필요

• 콜리메이터 렌즈와 초점 렌즈는 서랍형 설치 방식으로 장착되어 유지 보수 및 교체가 편리합니다.

• 내부에 수냉식 방열판을 채택하여 절단 헤드의 온도를 낮춰 수명을 향상시켰습니다.

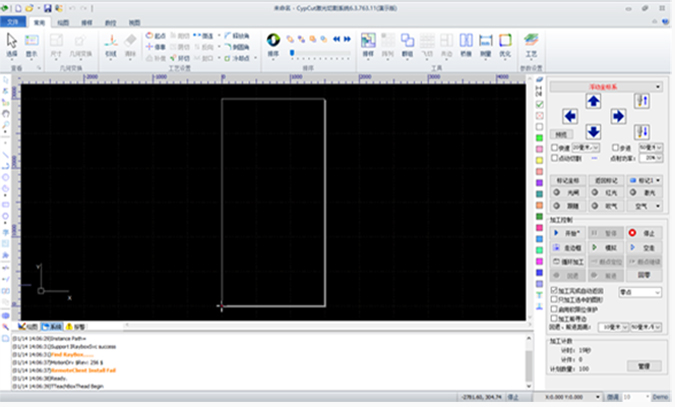

Professional Control Software

• DXF, PLT, LXD 및 기타 그래픽 데이터 형식 지원.

• Find edge: 최대 500mm/s의 고속으로 정밀한 시트 가장자리 찾기가 가능하며, 생산 요구 사항을 충족하는 옵션인 Find Edge 패턴도 제공합니다.

• 레이저 출력 제어, 비행 중 절단 및 점프, 중단점에서의 연속 절단, 자동 모서리 검색, 키홀 가공, 절단 헤드 제어 등을 지원합니다.

• 기술: 다양한 두께의 금속판에 대한 다중 피어싱 솔루션, 피어싱 슬래그 제거, 진동 억제, 폐쇄 루프 가스 제어, 대형, 중형 및 소형 윤곽 절단을 위한 분리 레이어 기술 등을 통해 기계 생산 능력을 확장할 수 있습니다.

수입 부품

• Automatic parallel compensation technology.

• lmprove processing range.

• Less mechanical components and motors cost.

• Increased running speed.

• Good dynamic response.

• High precision and speed, large inertia ratio.

• Stable performance and durability.

• Excellent dynamic response.

• Closed loop control method.

• Quiet,non-polluting, reliable and long-lasting.

• Achieve high precision and speed in cutting process.

• Excellent quality and stability, in accordance with internationalstandards.

Professional Water Chiller

• High precision temperature control function. Temperature control accuracy can reach ±1°C High temp. for QBH connection/ optics and low temp. for laser devices.

• Multiple alarm protection: The laser will stop working once it receives the alarm signal from the water chiller for protection purposes.

• Equipped with water pressure gauges, drain outlet with valve, and universal wheels. Water pres.sure gauges help monitor the discharge pressure of the water pump while universal wheels facilitate the moving of the chiller.

• Dualinlet and dual outlet connector& level gauge equipped. The Chiller inlet connects to the laser outlet connector. The Chiller outlet connects to the laser inlet connector.

• Cooling fan of famous brand installed. With high quality and low failure rate.

• Customized dust gauze is available and easy to take apart.

Other Important Accessories

S&A Chiller

Taiwan Precision Guide Rail

Taiwan Pinion and Rack

Imported Reducer

Imported Servo Motor

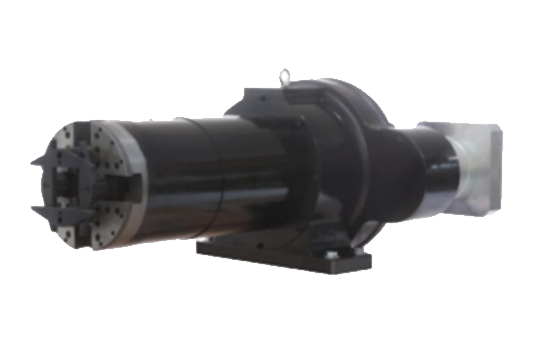

Full Stroke Pneumatic Chuck

Professional Clamp Design

Fractional Automatic Support Installation

• lt adopts a pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-220mm

• Automatic pneumatic chuck, adjustable and stable.

• Non-destructive pipe clamping.

• Fast automatic centering and clamping pipe.

• Gear transmission mode, higher transmission efficiency.

• lt employs intelligent tube support design,which can solve the deformation problemsin the process of long tube cutting.

Ande Services

품질 관리

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

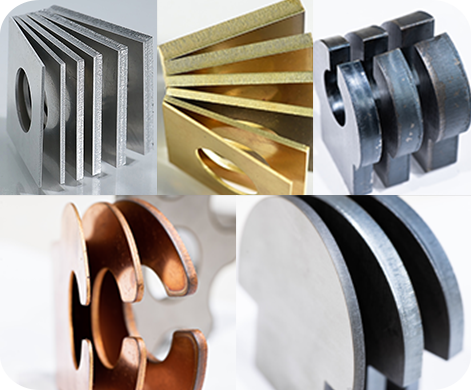

Cutting Samples

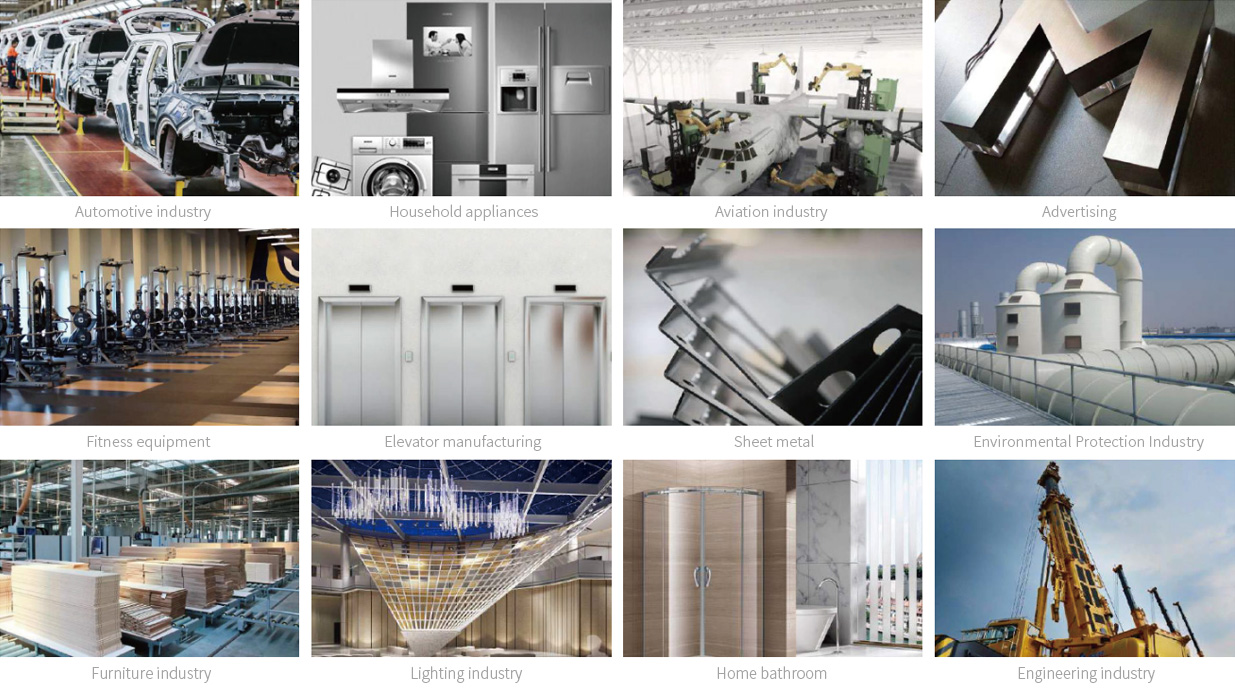

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.