Paramètres techniques

N° de modèle

AD T40

AD T70

Diamètre du tube

φ8-38mm

φ8-68mm

Longueur du tube

1000mm - 7000mm

Cutting Length

≤1000mm

Positioning Accuracy

±0.2mm

Repositioning Accuracy

±0.1mm

Vitesse maximale de déplacement

120m/min

Maximum Acceleration

1.5G

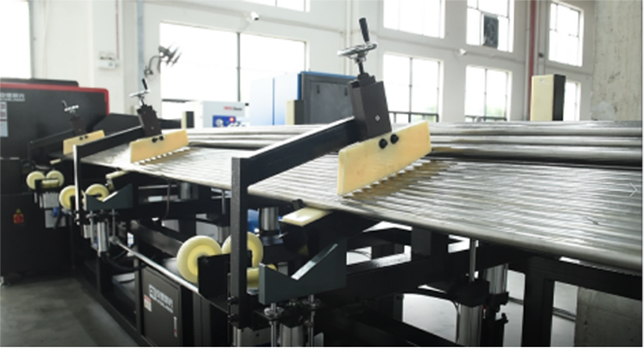

Fully Automatic in Bundle Loading Feeding and Cutting

Self-developed servo transmission system to ensure fast and accurate transmission execution.

Fully automatic in bundle loading, feeding and cutting, reducing employees’ work and saving labor cost.

High Speed Cutting

1 second per cut for the thin material, rapidly increasing production efficiency.

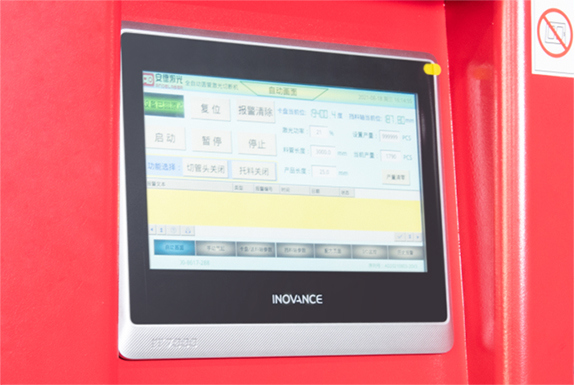

Simple Operation

The operation interface is easy to operate and no 3D drawing is required. The skill requirements for employees are simple.

Automatic Continuous Feeding

The shortest tail material can reach 0-40mm.

reducing material consumption.

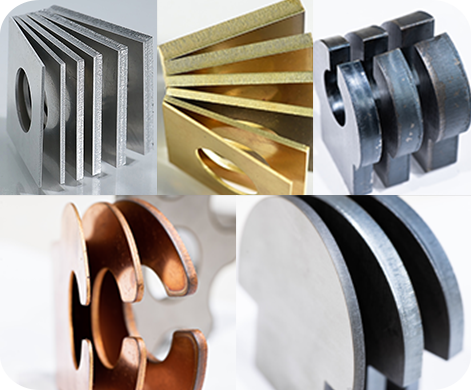

High Quality Cutting

The cutting surface is smooth without burrs. The automatic dislodging function is optional to meet the requirements of a clean inner wall without slag.

Configuration de haute qualité

• Plage de puissance de fonctionnement : 10 % à 105 %

• Qualité du faisceau : BPP < 2,5

• Durée de vie de la source de pompage : 100 000 h

• Sans entretien

• Completely sealed internal structure can avoid optical parts polluted by dust.

• The collimator lens and focus lens are equipped in a drawer installation way, which is convenient for maintenance and replacement.

• Adopting a water-cooling heat sink inside to reduce the temperature of the cutting head to improve its service life.

Ande Services

Contrôle qualité

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

Cutting Samples

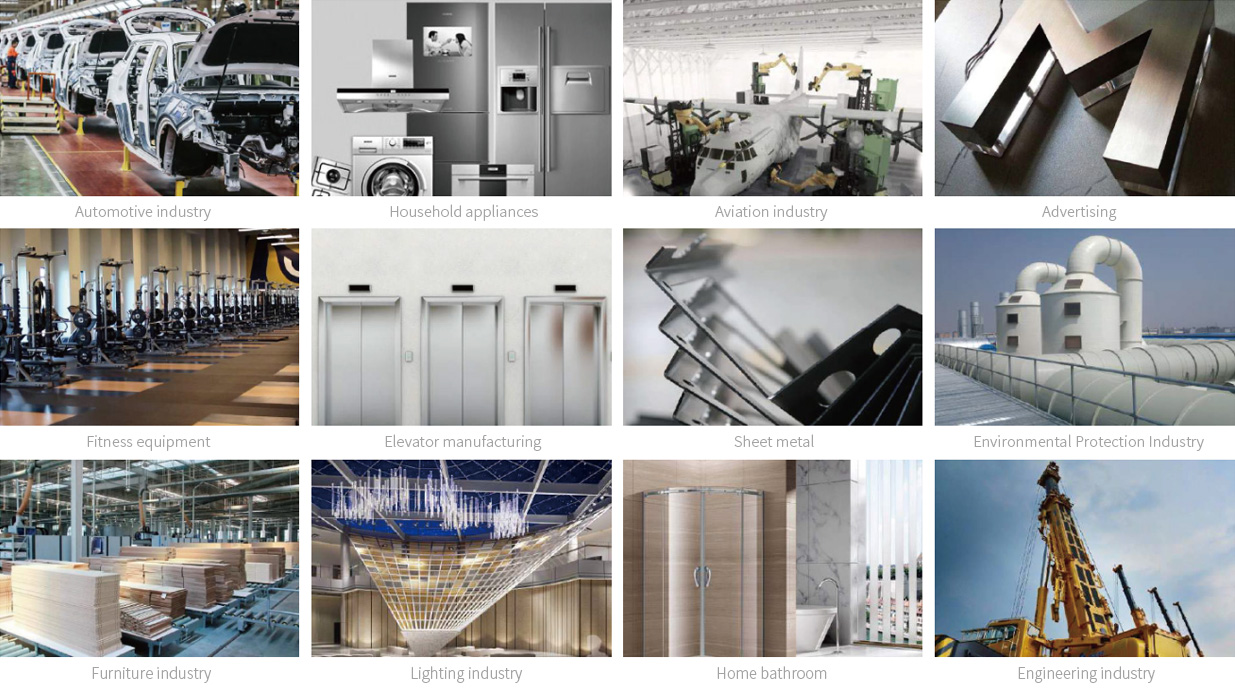

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.