Technische Parameter

Modell-Nr.

AD3015F

AD4020F

AD6020F

Schneidebereich

3000x1500mm

4000x2000mm

6000x2000mm

X/Y-Positioniergenauigkeit

±0.04mm/m

Maximale Bewegungsgeschwindigkeit

120m/min

Maximum Acceleration

1.0G

Laserleistung

1000W - 6000W

Max Loading Weight

650kg

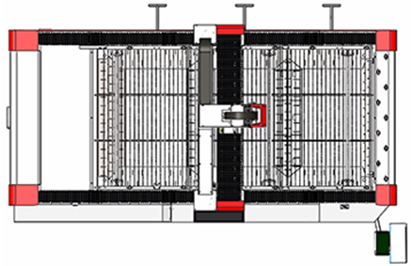

Exchange platform

• It can be cut at the worktable and loaded and unloaded at the same time to improve production efficiency; the platform ex-change time is less than 15s, and the large-format rapid ex-change saves time.

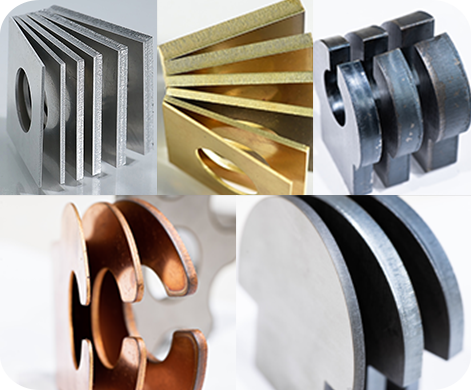

Suitable For Cutting A Variety Of Materials

• Suitable for cutting a variety of materials. No need for secondary processing, improves efficiency.

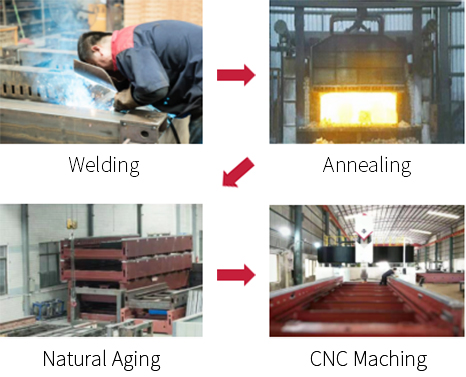

Bienenwaben-Förmige Stahlplatten-Schweißstruktur

One-piece Extruded Aluminum Beam

•Basierend auf den Metalleigenschaften von Aluminiumlegierungen aus der Luftfahrttechnik verfügt es über ein geringes Gewicht und eine hohe Steifigkeit, was eine Hochgeschwindigkeitsbewegung während der Laserbearbeitung gewährleistet.

•Perfekte dynamische Leistung. Unter der Voraussetzung einer zufriedenstellenden Genauigkeit kann ein Hochgeschwindigkeitsschneiden verschiedener Grafiken erreicht werden.

•Lange Lebensdauer, die Form bleibt maximal unverändert, um Schnittgenauigkeit und Produktqualität sicherzustellen.

Hochwertige Konfiguration

• Leistungsbereich: 10–105 %

• Strahlqualität: BPP <2,5

• Lebensdauer der Pumpquelle: 100.000 h

• Wartungsfrei

• Collimator lens and focus lens are equipped in drawers installation way, whichis convenient for maintenance and replacement.

• Adopting water-cooling heat sink inside to reduce the temperature of the cut-ting head to improve its service life.

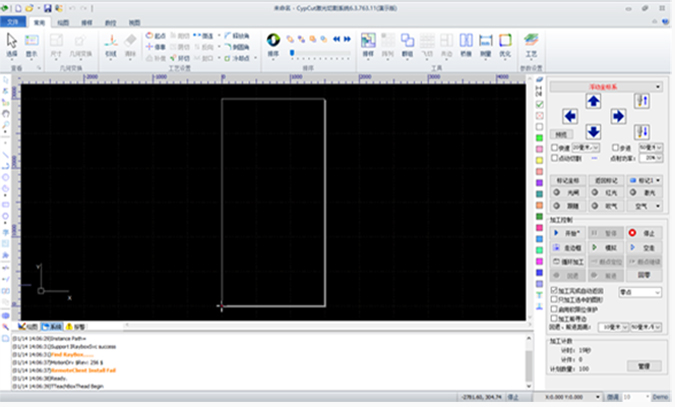

Professionelle Steuerungssoftware

• Unterstützung für DXF, PLT, LXD und andere Grafikdatenformate.

• Kante finden: bis zu 500 mm/s hohe Geschwindigkeit mit präziser Blattkantenfindung, bietet auch optionale Kantenfindungsmuster, um Ihren Produktionsanforderungen gerecht zu werden.

• Unterstützt Laserleistungssteuerung, Schneiden und Springen während des Flugs, kontinuierliches Schneiden an einem Haltepunkt, automatische Kantensuche, Schlüssellochverarbeitung, Schneidkopfsteuerung usw.

• Technik: mehrere Lochlösungen für Metallbleche unterschiedlicher Dicke; Entfernung von Lochschlacke; Vibrationsunterdrückung; Gasregelung im geschlossenen Regelkreis; separate Schichttechnik für große, mittlere und kleine Konturschnitte, alles zur Erweiterung der Produktionskapazität Ihrer Maschine.

Importierte Komponenten

• Automatic parallel compensation technology.

• lmprove processing range.

• Less mechanical components and motors cost.

• Increased running speed.

• Good dynamic response.

• High precision and speed, large inertia ratio.

• Stable performance and durability.

• Excellent dynamic response.

• Closed loop control method.

• Quiet,non-polluting, reliable and long-lasting.

• Achieve high precision and speed in cutting process.

• Excellent quality and stability, in accordance with internationalstandards.

Professional Water Chiller

• High precision temperature control function. Temperature control accuracy can reach ±1°C High temp. for QBH connection/ optics and low temp. for laser devices.

• Multiple alarm protection: The laser will stop working once it receives the alarm signal from the water chiller for protection purposes.

• Equipped with water pressure gauges, drain outlet with valve, and universal wheels. Water pres.sure gauges help monitor the discharge pressure of the water pump while universal wheels facilitate the moving of the chiller.

• Dualinlet and dual outlet connector& level gauge equipped. The Chiller inlet connects to the laser outlet connector. The Chiller outlet connects to the laser inlet connector.

• Cooling fan of famous brand installed. With high quality and low failure rate.

• Customized dust gauze is available and easy to take apart.

Ande Services

Qualitätskontrolle

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

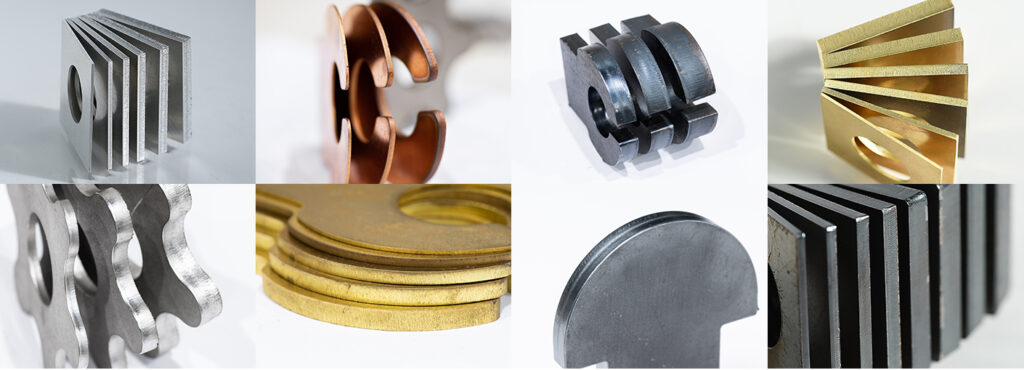

Cutting Samples

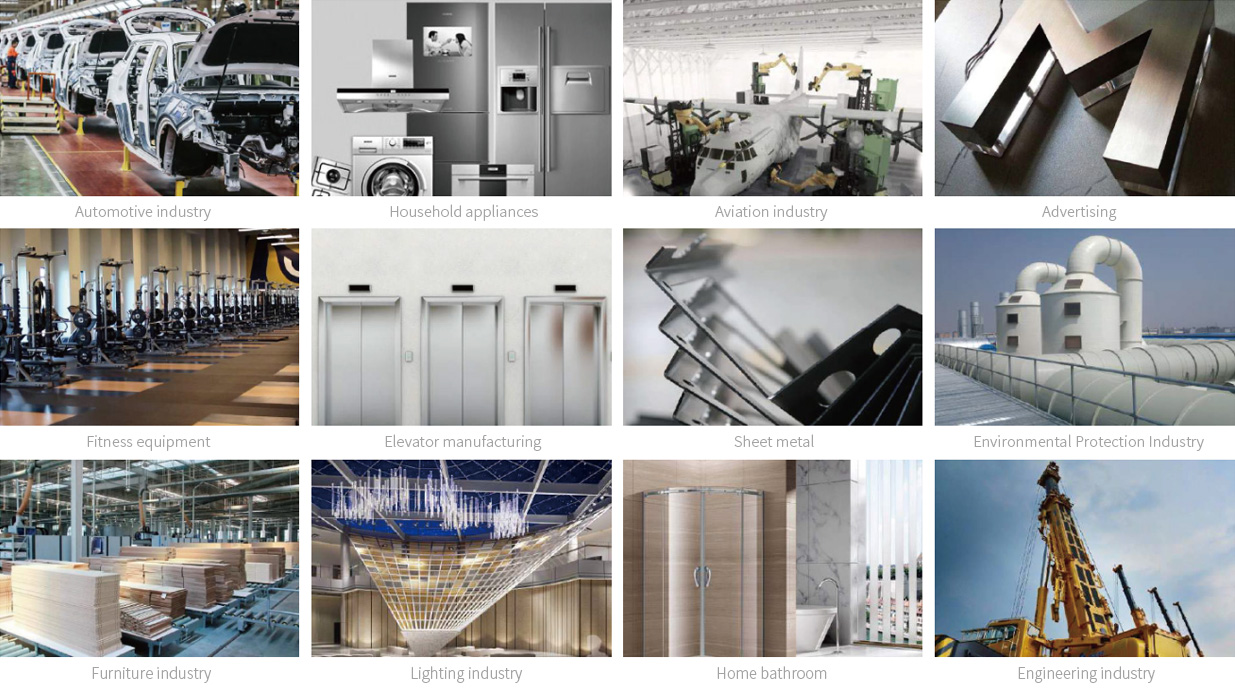

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.